- General Details

- Technical Details

- Documents

- Comments

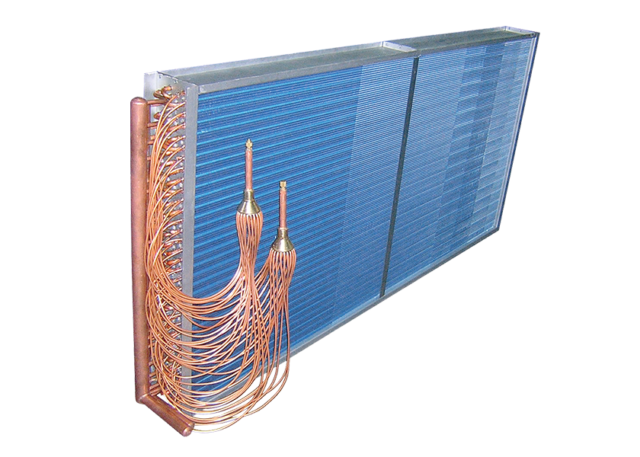

Dx evaporators air handling units Pool dehumidification units are widely used for rooftop and other special needs. Dx coils are manufactured in 2 to 12 rows according to the capacity requirement. Dx coils works at 65 C horizontally or vertically. A distributor is used to provide proportional refrigerant distribution at the inlet of the liquid line. Gas and liquid line pipe connections are manufactured as right and left sided. Gas and water line pipe connections are manufactured as welded or with union connection. The sensor housing is left as standard in all DX coils. Dx Coil outer cassette is manufactured completely from galvanized or stainless steel sheet. Dx Coil fins are produced from a special alloy aluminum foil with a thickness of 130 to 200 microns. Dx Coil fins are manufactured as epoxy coated. The distance between the two blades in Dx coils are 2.1 mm, 2.5 mm and 3 mm. The edge cuts of the fins can be made straight or wavy. Copper pipes used in the production of Dx coils are 0.35 or 0.40 mm and 3/8 or 1/2 in diameter. All Dx coils are manufactured with 32-28 or 25-22 staggered geometry. Dx coils are manufactured with 1 to 12 circuits according to customer needs in different capacities and sizes according to all kinds of special project needs. Dx coils produced are tested at 40 bar pressure and shipped under pressure. Dx coils work with 134, 404, 407 and 410 refrigerant. All Dx coils can be made optionally with horizontal and vertical outlets. In order to provide a price advantage, it is also possible to order with 0.7 mm aluminum pipe.